Specialty Shaped & Bottom-Up Roller Shades.

Conston Tension Shade Models:

Straight Hem Bottom Up Shades

Manual or motorized shades for rectangular windows up to 16’ wide.

Angled & Peaked Hem Shades

Special fully retracting shades for windows that feature an angled or peaked top.

CTS & CTS-L Models:

CTS Bottom-Up Shades

A rectangular heavy duty 3-sided bottom-up shade for interior & exterior applications.

Up to 160” wide x 126” tall

4” x 4” roller housing at bottom

2.28” wide x 1.9” deep zip track side channels

3 sided system: Roller housing at bottom, left track & right track.

No visible tension cables

CTS-L Bottom-Up Shades

A rectangular heavy duty 3-sided bottom-up shade for large interior & exterior applications.

Up to 192” wide x 192” tall

5” x 5” roller housing at bottom

2.29” wide x 2.02” deep zip track side channels

3 sided system: Roller housing at bottom, left track & right track.

No visible tension cables

Conston Product Details:

The Secret Sauce

We use a special crowned stainless spring steel which we embed in the hem pocket of each fully retracting specialty shaped shade. This allows the hem to be stiff when the shade is deployed while also allowing the hem to be flexible enough to wrap the roller when retracting.

The Conston Spring Rail

The 2.2” deep x 2.7” tall Conston spring rail houses the multiple springs required to lift our specialty shaped and bottom-up shades. Type 301 stainless steel is used for the constant force spring while super-strong fiber cording made from ultra-high molecular weight polyethylene is used for the low visibility cording.

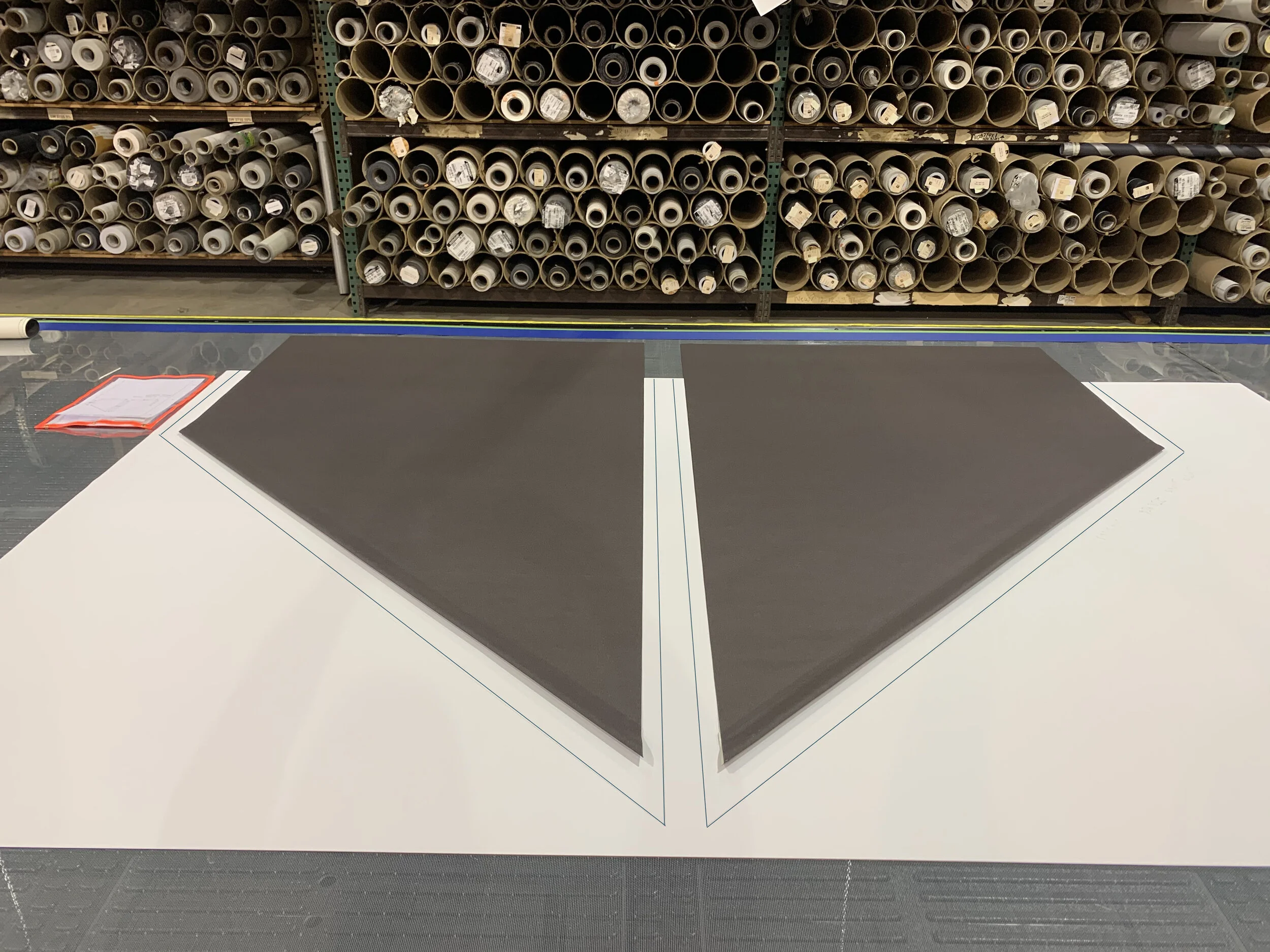

Precision Cutting

With every specialty shaped project we plot the window opening and then build the shade within it to ensure precise fitment.

Motorization Options.

Our Motors

We can produce your specialty shades using our Somfy, NICE, Gaposa or Automate motors and controls.

Your Motors

Or if you prefer you can supply us with your own tubular motors from practically any brand.

Conston shades require motors with torque >3nm

CTS & CTS-L require high torque motors >10nm

Plotting & Fabric Cutting

The fabric panels for all specialty shaped, bottom-up, skylight and exterior shades are precision cut with our Autometrix XY integrated cutting system:

Custom, Precise Engineering

We plot every specialty shaped project to ensure exact fitment.